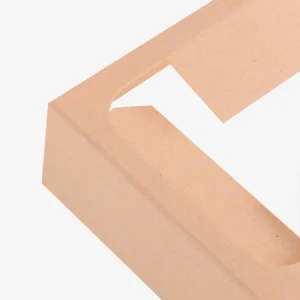

Tuck End Snap Lock Bottom

Snap lock bottom boxes have their bottoms that can be used as locks. These are flaps that can be interlocked. When all of the flaps are interlocked, they assemble to produce a sturdy lock that cannot be open easily during transportation or other kinds of movement. This lock holds the products inside firmly and does not let them slip out of the container. They can be a bit harder to manufacture, but the security they provide beats the effort that is needed to produce them. Even more, flaps can be added at the bottom for reinforced protection if the default structure is not enough. At the place where flaps are locked, additional locks can be used to ensure that the protection is firm and unswerving during transit. This added protection works simply. First of all, a big panel is inserted for locking. After that, two dust panels are used to protect goods from getting dirty. If more protection is still required, another locking panel is added to Tuck End Snap Lock Bottom. The customization it gives is the best in all protective materials.

GET CUSTOM QUOTE

Snap lock bottom boxes have their bottoms that can be used as locks. These are flaps that can be interlocked. When all of the flaps are interlocked, they assemble to produce a sturdy lock that cannot be open easily during transportation or other kinds of movement. This lock holds the products inside firmly and does not let them slip out of the container. They can be a bit harder to manufacture, but the security they provide beats the effort that is needed to produce them. Even more, flaps can be added at the bottom for reinforced protection if the default structure is not enough. At the place where flaps are locked, additional locks can be used to ensure that the protection is firm and unswerving during transit. This added protection works simply. First of all, a big panel is inserted for locking. After that, two dust panels are used to protect goods from getting dirty. If more protection is still required, another locking panel is added to Tuck End Snap Lock Bottom. The customization it gives is the best in all protective materials.

GET CUSTOM QUOTE

| Dimension | L + W <= 20 inch; H <= 26 inch |

| Quantities | 100 - 500,000 |

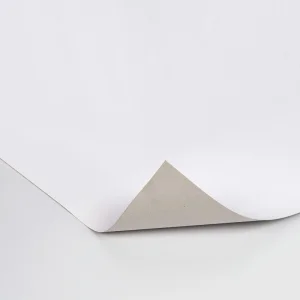

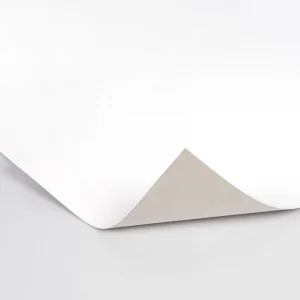

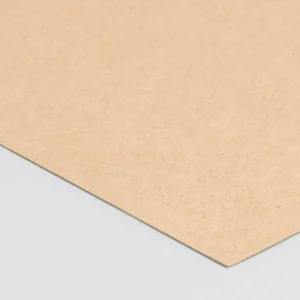

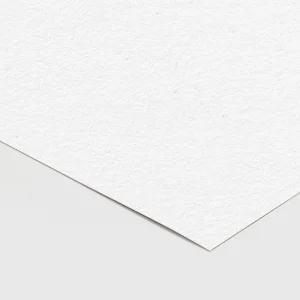

| Paper Stock | 12pt up to 24pt White cardstock, 18pt up to 24pt SBS, 18pt up to 24pt Kraft cardstock, Corrugated stock. |

| Colors | Plain White/ Brown Kraft, CMYK, PMS, Special Colors(Metallic Silver, Metallic Gold) |

| Finishing | Gloss AQ (Default),Gloss UV, Matt UV |

| File Upload |

Die-line and design in separate layers PMS swatch noted if applicable |

| Proof | Digital Proof (press-ready file) confirmed by customer. |

| Turnaround | 8-10 business days to print and ship, after the final approval(FREE Shipping) |

| Shipping | Flat Pack |

.webp)

.webp)

.webp)